Unident Dental High Speed Spindle/ Alloy Grinder M-801

$ 19.50 – $ 30.62Price range: $ 19.50 through $ 30.62

1 HP alloy grinder with 24000 RPM spindle for precision dental work

| Title | Quantity | Price |

|---|---|---|

| Bulk/tiered discount | 2 - 5 | 1% $ 19.31 |

| Bulk/tiered discount | 6 - 10 | 2% $ 19.11 |

| Bulk/tiered discount | 11 - 20 | 4% $ 18.72 |

| Bulk/tiered discount | 21 - 50 | 5% $ 18.53 |

| Bulk/tiered discount | 51 + | 7% $ 18.13 |

Features

Description

The Unident Dental High Speed Spindle/Alloy Grinder M-801 stands as a pinnacle in precision dental equipment, meticulously designed to meet the demanding needs of dental professionals. Renowned for its robust construction and unparalleled performance, this grinder boasts a heavy-duty 1 HP motor, ensuring reliability and longevity in its operation. Equipped with two high-quality ball bearings, it guarantees stability and smooth functionality.

This model showcases exceptional versatility, functioning as both a high-speed spindle and an alloy grinder, meeting various dental procedural requirements. With a formidable spindle RPM of 24000, it delivers precision and efficiency in dental material manipulation. Notably, its design is optimized for operation without suction, offering convenience without compromising on its impressive capabilities.

Crafted by industry-leading manufacturers, the Unident Dental High Speed Spindle/Alloy Grinder M-801 surpasses expectations with its superior build quality and precise engineering. Its integration into dental practices enhances workflow efficiency, ensuring accurate and intricate dental work.

Whether for shaping, grinding, or intricate detailing of dental alloys, this grinder stands as an indispensable tool, sought after by professionals seeking uncompromising quality and performance in their practice. It remains a staple, meeting the exacting standards of modern dentistry with its reliability and precision.

Key Specifications

- Model: M-801

- Function: High-speed spindle and alloy grinder

- Motor Power: 1 HP

- Bearings: Equipped with two high-quality ball bearings

- Spindle RPM: 24000 RPM

- Suction: Operates without suction

- Application: Dental material manipulation

- Versatility: Ideal for shaping, grinding, and detailing

Packaging

- 1 x Spindle/Alloy Grinder Machine M-801 with 1 Pc extra belt

Direction to Use

Setup and Safety Precautions:

- Place the grinder on a stable, level surface.

- Ensure the power source matches the grinder’s specifications.

- Wear appropriate personal protective equipment (PPE), including safety goggles and gloves.

Power On:

- Connect the grinder to a suitable power supply.

- Turn on the power switch located on the machine.

Material Preparation:

- Securely place the dental alloy or material to be worked on in the designated area.

- Ensure the material is firmly held and won’t move during the grinding process.

Operation:

- Adjust the speed settings if applicable to suit the task at hand.

- Activate the spindle by following the specified operational procedures.

- Begin grinding or shaping the dental material with controlled movements.

- Use appropriate grinding attachments based on the desired finish or detailing required.

Monitoring and Control:

- Continuously monitor the grinding process for precision and accuracy.

- Avoid excessive pressure or force while grinding to prevent damage to the material or the grinder.

Post-Operation:

- Once the desired shape or finish is achieved, turn off the grinder.

- Disconnect the power supply and clean the machine thoroughly.

- Store the grinder in a safe and dry location, away from moisture or extreme temperatures.

Maintenance:

- Follow the manufacturer’s guidelines for routine maintenance.

- Regularly inspect the machine for any signs of wear, damage, or loose components.

- Lubricate or replace parts as recommended by the manufacturer to ensure optimal performance.

1. We offer Worldwide Shipping by Courier via Air or Sea mode.

2. Product will be dispatched within 5-7 working days.

3. Delivery will take a maximum of 7-15 days, based on the shipping option you choose.

4. Kindly check customs restrictions and rules in your country for specific products, mostly 99% shipments are cleared and delivered smoothly.

5. For Bulk inquiries or customized manufacturing please contact us.

Product Enquiry

- Medical Supplies

- Nursing Supplies/Patient Care

- Health & Nutrition

- Wound Care & Dressings

- Medical Equipment

- Ophthalmic Supplies

- Diagnostic Instruments

- Diagnostic & Imaging Supplies

- Orthopaedic & Trauma

- Cardio Thoracic Surgery

- Dental Products

- Dental Equipment

- Restoratives

- Patient Education

- Offers

- Dental Models

- Clinical Problem Solvers

- Dental Consumables

- Orthodontics

- Oral Surgery

- Student Section

- Periodontics

- Cosmetic Dentistry

- General Dentistry

- Sterilization

- Endodontics

- Kits

- Medical Supplies

- Equipments

- Laboratory

- Implantology

- Instruments

- Basic Dental Products

- Paedodontics

- Preventives

- Corona Safety

- Prosthodontics

- Rative Next

- Dental Furniture

- Lab Supplies

- Dialysis Supplies

- Mobility Aids

- Anatomical Models

- Point of Care Testing

- Cath Lab Products

- Gloves

- Medical Simulators

- Rehabilitation

- Medical Accessories

- Cleaning and Waste Management

- Hearing Aids

- Medical Clothing

- Respiratory & Anaesthesia Supplies

- Hospital Apparel, Linen and Personal Protection

- Sterilization, Antiseptics & Disinfectants

- IV, Infusion & Transfusion

- Surgical Instruments

- Medical Equipments

- Surgical Supplies

- Braces, Splints & Supports

- Medical Instruments

- Surgical Sutures

- Body Weight Machine

- Needles & Syringes

- Dental Supplies

- Urology, Ostomy & Incontinence

- Gynecology & Infant Care

- Respiratory Care Products

- Veterinary

- Agro Chemicals

- Category

Related Products

Features:

3M Cavilon No Sting Barrier Film Wand

Volume: 1/3 ml

Type: Wand

Box of 25

Alcohol free

Features:

3M Crown Crimping Pliers

Crown Crimping Pliers

Small Size

Lightweight

Easy to Use

Features:

3M Attest Biological Indicator 1264 for EO Sterilization

Box of 100

Biological indicator

Green colour-coded cap

For EO Sterilization

Features:

3M Disposable Surgeon Cap

Box of 100

Disposable

Comfortable to wear

Allow total coverage of head hair

Features:

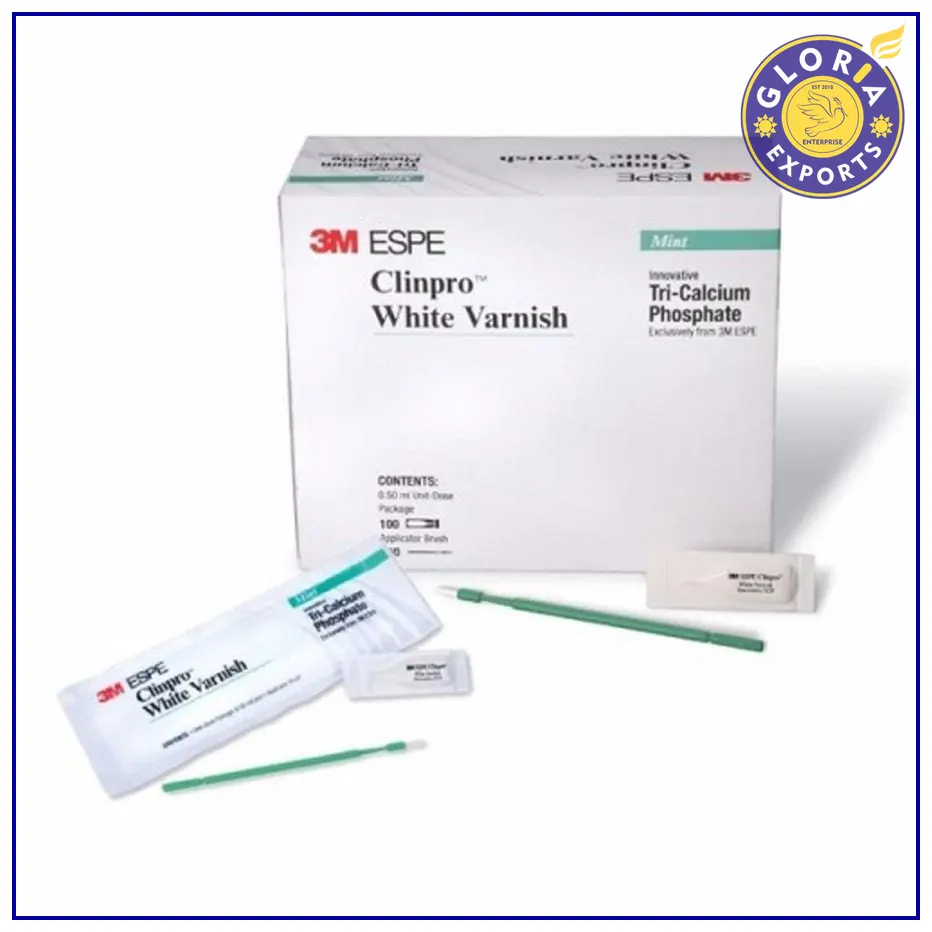

3M Clinpro Dental Varnish

Colour: White

5% Sodium Fluoride

Steady Fluoride Release

Easy to Apply

Out of stock

Features:

3M Aplicap Activator

Aplicap Activator

For Easy Activation

Lightweight

Durable

Features:

3M Comply Bowie-Dick Test Pack 1233

Case of 30 Packages

Early warning sheet

Easy to read test sheet

Lead free ink

Features:

3M Clinpro Dental Sealant

Long-lasting Protection Against Caries

Colour Change Technology

Low Viscosity

Bonds to Enamel

Features:

3M Avagard D Hand Sanitizer with Moisturizers 61% w/v Ethyl Alchohol

Size: 50/500 ml

Kills harmful bacteria

Dries quickly

Gentle on skin

Out of stock

Features:

3M Attest Biological Indicator 1262 Test Pack for Steam

Box of 100

Biological indicator

Accurate result

Brown colour-coded cap

Features:

3M Avagard Surgical Hand Antiseptic Hand Sanitizer

Size: 500/1200 ml

Dispenser/Wedge bottle

Effectively kills bacteria

Skin friendly

Out of stock

Features:

3M Cavit G Temporary Filling Material

Volume: 28g

Quick & Void-free Curing

Completely Removable without Burs

Simple to Apply